Strand woven bamboo flooring is one of the most popular options for homeowners and builders seeking sustainable, durable, and aesthetically pleasing flooring. Known for its high density and hardness, strand woven bamboo surpasses traditional hardwoods like oak and maple in terms of strength and resilience. But what makes strand woven bamboo so dense? In this blog, we will explore the key factors behind the material's remarkable density, its unique manufacturing process, and the benefits that arise from its structural properties.

What is Strand Woven Bamboo Flooring?

Before diving into the reasons behind its high density, it's essential to understand what strand woven bamboo flooring is and how it differs from other types of bamboo flooring. Bamboo flooring is typically available in three main types:

- 1. Horizontal Bamboo Flooring – Layers of bamboo are glued horizontally, showing the natural bamboo "knuckles" or nodes.

- 2. Vertical Bamboo Flooring – Bamboo strips are arranged vertically, creating a more uniform grain appearance.

- 3. Strand Woven Bamboo Flooring – The bamboo fibers are shredded, compressed, and woven together using high-pressure techniques, resulting in a stronger, more compact product.

Among these, strand woven bamboo is the densest and hardest, making it the preferred choice for high-traffic areas or places requiring maximum durability.

1. The Strand Woven Manufacturing Process

The manufacturing process of strand woven bamboo flooring is one of the primary reasons behind its high density. Unlike traditional wood flooring, which is made by cutting planks from logs, strand woven bamboo flooring involves a more complex process:

- - Harvesting Bamboo: Moso bamboo, the species most commonly used for strand woven flooring, is harvested at its peak strength, typically after 5-7 years of growth. Bamboo grows rapidly, making it an incredibly renewable resource.

- - Splitting and Shredding: The bamboo culms (stems) are split and shredded into long, thin strands. This is a crucial step in preparing the material for the weaving process. By shredding the bamboo, its natural fibers are exposed, creating a stronger structure once the strands are recombined.

- - Boiling and Drying: The shredded bamboo strands are boiled to remove sugars, starches, and other organic materials that could lead to mold or pest infestations. Once boiled, the bamboo is dried thoroughly to prepare it for the next phase.

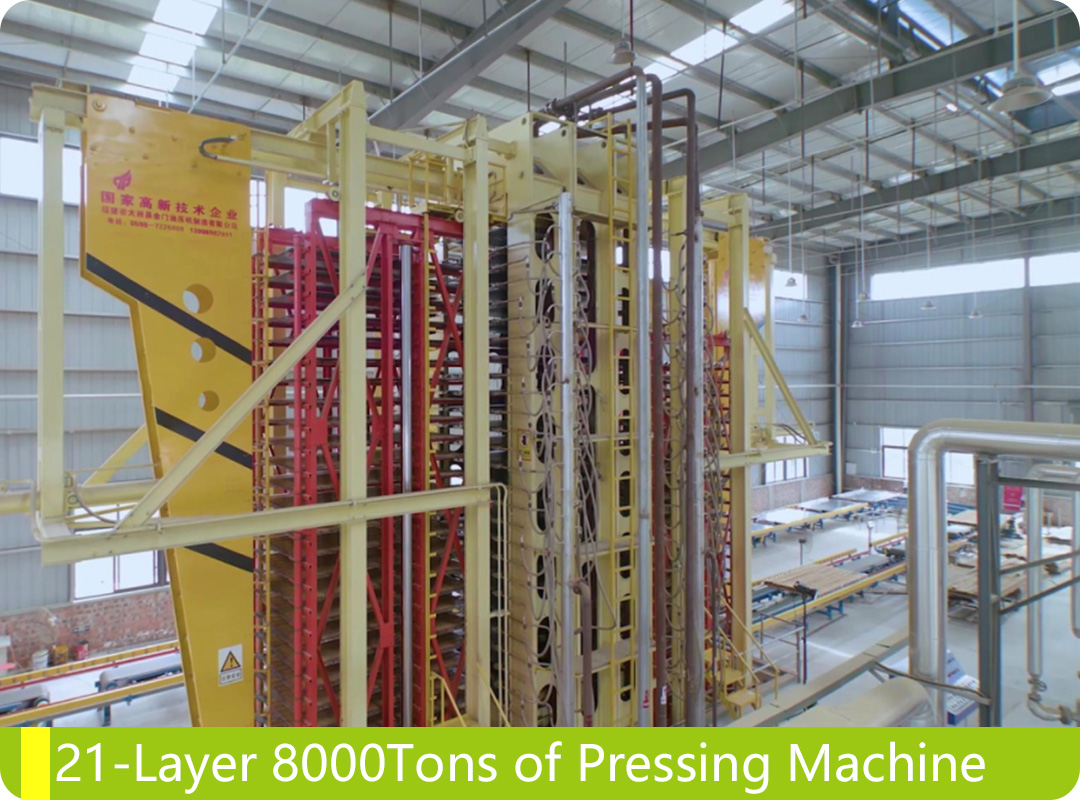

- - Compression and Bonding: The dried bamboo strands are woven together, then placed in molds where they are compressed under extreme pressure and bonded using adhesives or resins. This intense compression results in the material's dense structure, much denser than standard hardwood flooring.

- - Curing and Cutting: Once compressed, the material is cured, cut into planks, and coated with a protective finish, usually involving multiple layers of UV-resistant coatings for added durability.

This process of shredding, compressing, and bonding bamboo strands is the key to achieving the material's extraordinary density. The weaving and compression essentially “pack” the bamboo fibers tightly together, eliminating air pockets and increasing the material's overall hardness.

2. Bamboo's Natural Strength and Fiber Composition

Another factor contributing to strand woven bamboo's high density is the natural properties of bamboo itself. Bamboo is technically a grass, but it has a fibrous structure that is similar to wood. The cellular makeup of bamboo is dense, especially in species like Moso bamboo, which is commonly used for strand woven flooring. The fibers in bamboo are aligned vertically, providing exceptional tensile strength. This natural fiber alignment makes bamboo resilient against bending and breaking. When these fibers are shredded and compressed during the strand woven manufacturing process, they become even more compact, resulting in a product that is both hard and dense. In terms of hardness, strand woven bamboo ranks higher on the Janka Hardness Scale than most hardwoods. The Janka test measures the resistance of wood to wear and denting, and strand woven bamboo scores around 3,000 pounds-force (lbf), compared to oak, which scores around 1,290 lbf. This high score is a testament to the strength and density of strand woven bamboo.

3. High-Pressure Compression and Adhesives

As mentioned earlier, the high-pressure compression applied to bamboo strands during the manufacturing process is a major factor in its density. The pressure used in this process can reach up to 2,500 tons. This intense compression forces the bamboo fibers to bond tightly, reducing gaps or weaknesses within the material and effectively creating a near-solid plank. The adhesives or resins used during this process also play a role in enhancing the density of strand woven bamboo. These binders help secure the individual bamboo strands together, filling in any microscopic voids and adding to the overall strength of the final product. The combination of high pressure and strong adhesives results in flooring that is incredibly dense and stable.

4. Durability and Performance of High-Density Flooring

The high density of strand woven bamboo flooring comes with numerous benefits that make it an attractive option for various applications:

- - Increased Hardness: As mentioned, strand woven bamboo flooring is harder than many traditional hardwoods, which means it is less prone to dents, scratches, and wear, even in high-traffic areas.

- - Resistance to Moisture: Due to its dense structure, strand woven bamboo is more resistant to moisture and humidity than other types of bamboo flooring. This makes it an excellent choice for areas like kitchens, bathrooms, or basements, where moisture can be a concern.

- - Durability in High-Traffic Areas: The density and hardness of strand woven bamboo make it particularly suitable for commercial spaces, office buildings, or homes with heavy foot traffic. Its durability ensures it will stand up to years of use without showing signs of significant wear.

- - Stability: The tightly compressed structure of strand woven bamboo also gives it enhanced dimensional stability. It is less likely to expand, contract, or warp due to changes in temperature or humidity, which can be an issue with less dense flooring materials.

5. Environmental Benefits of Strand Woven Bamboo

Beyond its density and durability, strand woven bamboo flooring is also an environmentally friendly choice. Bamboo grows incredibly fast, with some species capable of growing up to 3 feet in just 24 hours. Unlike hardwood trees, which can take decades to mature, bamboo reaches full maturity within 5-7 years. This rapid growth makes bamboo one of the most renewable resources on the planet. Furthermore, the harvesting of bamboo does not involve cutting down the entire plant. Only the mature stems are harvested, allowing the plant to continue growing and regenerating without causing soil degradation or deforestation.

Strand woven bamboo flooring is a marvel of engineering, combining the natural strength and rapid renewability of bamboo with a manufacturing process that enhances its density and durability. The high-pressure compression of bamboo strands creates a flooring material that is harder than many traditional hardwoods, resistant to moisture, and perfect for high-traffic areas. Its dense structure, combined with its environmental benefits, makes strand woven bamboo an excellent choice for eco-conscious homeowners and builders seeking both performance and sustainability. Whether for residential or commercial use, strand woven bamboo flooring offers a winning combination of strength, durability, and environmental responsibility, all wrapped up in a beautiful, natural aesthetic.